Proper peptide storage and handling are crucial for maintaining peptide integrity, stability, and biological activity. Even the highest-quality peptides can degrade rapidly if improperly stored or handled, leading to experimental failures, inconsistent results, and wasted resources. This comprehensive guide provides best practices for peptide storage, reconstitution, aliquoting, and handling to maximize stability and ensure reliable research outcomes.

Understanding Peptide Stability

Peptides are inherently less stable than small molecule drugs due to their chemical structure and susceptibility to various degradation pathways. Understanding what causes peptide degradation informs proper storage and handling strategies.

Chemical Degradation Pathways

Several chemical processes can degrade peptides over time:

Oxidation

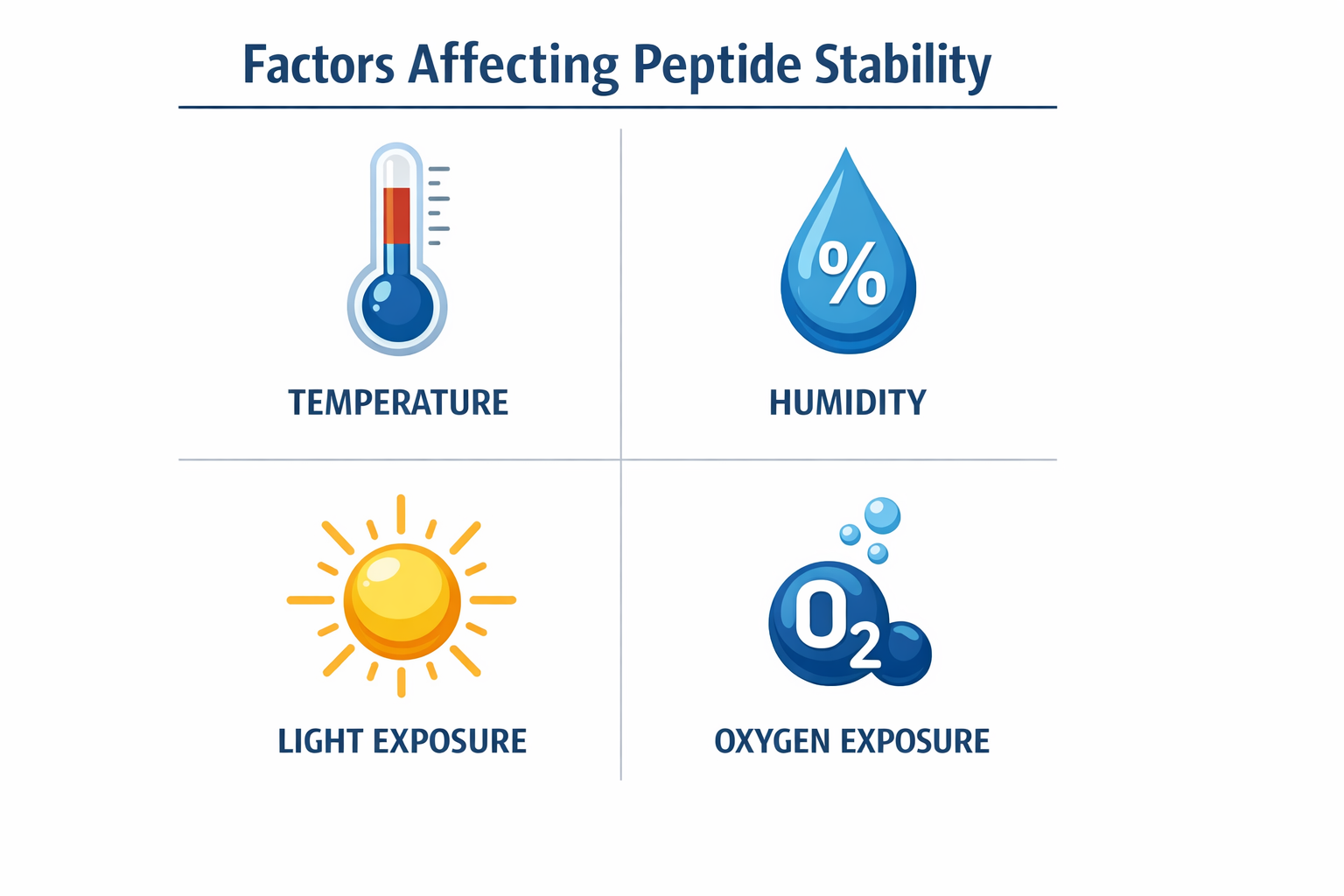

Amino acids with sulfur-containing side chains (methionine, cysteine) are particularly susceptible to oxidation. Oxidation alters peptide structure, often reducing or eliminating biological activity. Exposure to air, light, and oxidizing agents accelerates this process.

Hydrolysis

Water can break peptide bonds, especially at susceptible sites like aspartic acid-proline sequences. Hydrolysis essentially cuts the peptide chain, creating truncated fragments. Hydrolysis accelerates at temperature extremes and non-neutral pH.

Deamidation

Asparagine and glutamine residues can undergo deamidation, where the amide group is lost and replaced with a carboxyl group. This alters peptide charge and can affect activity. Deamidation rates increase with temperature and non-neutral pH.

Racemization

L-amino acids can convert to D-amino acids, particularly at high pH or elevated temperatures. This changes peptide structure and typically reduces activity.

Aggregation

Peptides can associate with each other, forming dimers, oligomers, or larger aggregates. Aggregation reduces the amount of active monomeric peptide and can completely eliminate activity. Hydrophobic peptides are particularly prone to aggregation.

Physical Degradation

Beyond chemical changes, physical processes affect peptide integrity:

Adsorption

Peptides can adsorb to container surfaces (glass, plastic), effectively removing them from solution. This is particularly problematic at low concentrations where a significant fraction of the peptide may bind to surfaces.

Precipitation

Changes in temperature, pH, or solvent composition can cause peptides to precipitate out of solution, forming visible particles or cloudy solutions. Precipitated peptides may not fully re-dissolve and often show reduced activity.

Temperature Effects

Temperature profoundly influences degradation rates. As a general rule, chemical reactions approximately double in rate for every 10°C temperature increase. This means peptides degrade much faster at room temperature than when frozen.

Lyophilized Peptide Storage

Most research peptides are supplied as lyophilized (freeze-dried) powders, which offer enhanced stability compared to solutions.

Optimal Storage Conditions

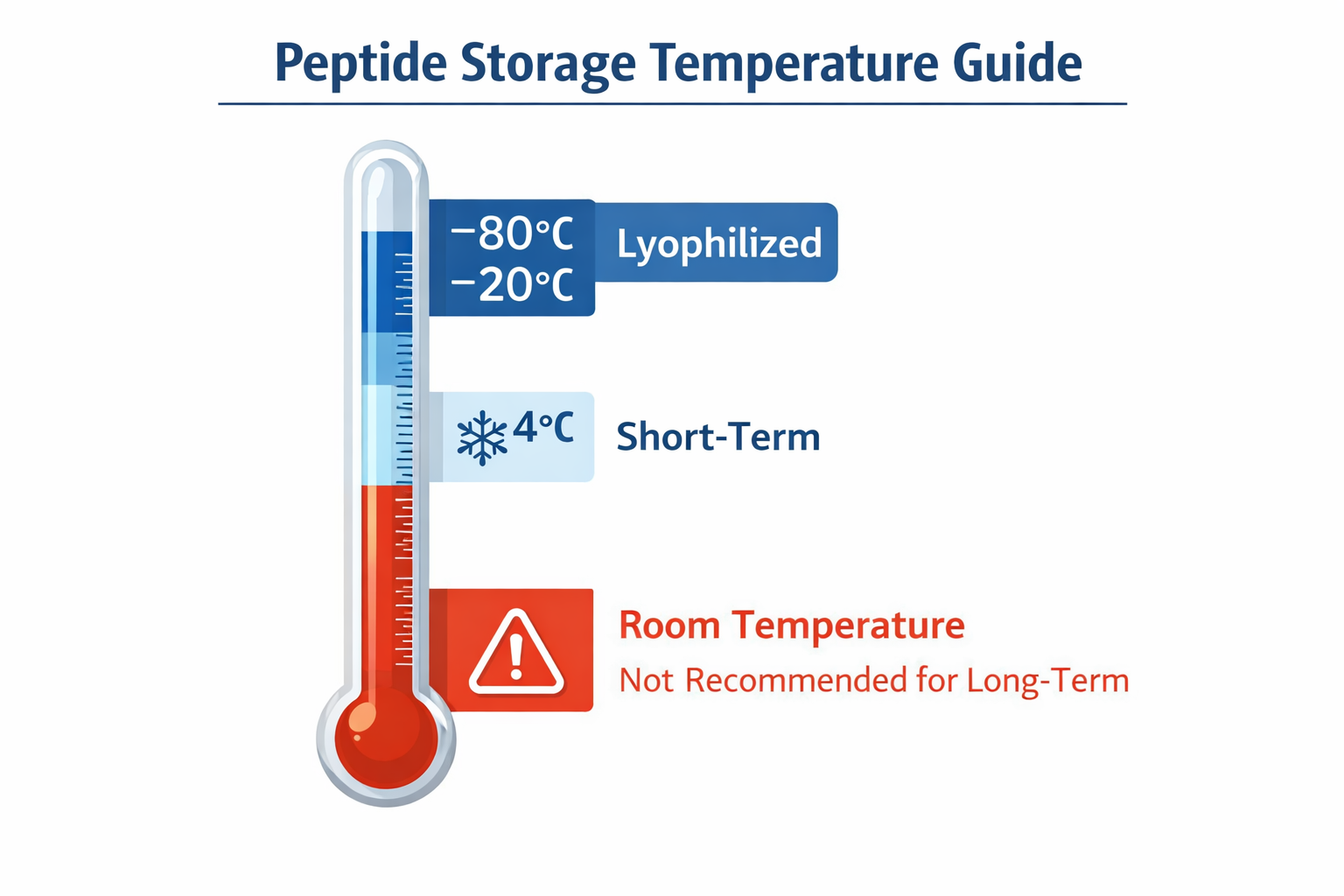

For maximum stability of lyophilized peptides, store at -20°C or -80°C in a standard laboratory freezer. Ultra-low temperature (-80°C) offers maximum stability but -20°C is adequate for most peptides when properly packaged.

Keep peptides in a desiccated environment using desiccant packets to absorb moisture. Moisture exposure can initiate degradation even in solid state. Store in original sealed vials when possible, as manufacturer packaging is designed to protect peptides. Once opened, reseal tightly and return to freezer immediately.

Protect from light by storing in original amber vials or wrapping containers in aluminum foil, as many peptides are photosensitive. Avoid repeated temperature fluctuations by storing in a freezer not frequently opened, or in an area of the freezer with minimal temperature variation.

Storage Duration

When properly stored, many lyophilized peptides remain stable for years. However, stability varies by sequence, with peptides containing oxidation-prone residues showing shorter stability, and peptides with hydrolysis-susceptible sequences degrading faster.

Manufacturers typically guarantee stability for 1-2 years when stored properly, though many peptides remain usable longer. For critical experiments, verifying peptide integrity (by HPLC or mass spectrometry) before use provides confidence, especially for older material.

Short-Term Storage

If peptides will be used within weeks, storage at -20°C is appropriate. Avoid storing at 4°C for extended periods, as degradation proceeds significantly faster than at freezing temperatures. Never store at room temperature except for immediate use (minutes to hours).

Bringing Peptides to Room Temperature

Before opening a frozen vial, allow it to warm to room temperature in a desiccator or with desiccant. This prevents moisture condensation on the cold peptide, which can initiate degradation. Warming typically takes 15-30 minutes depending on vial size.

Once at room temperature, open briefly to access peptide, then reseal and return to freezer promptly.

Reconstitution Best Practices

Reconstituting lyophilized peptides requires care to ensure complete dissolution while minimizing degradation.

Selecting Appropriate Solvents

Solvent choice depends on peptide properties, particularly hydrophobicity:

Water and Aqueous Buffers

Hydrophilic peptides (containing many charged or polar residues) typically dissolve readily in water, physiological saline (0.9% NaCl), PBS (phosphate-buffered saline), or other aqueous buffers. Distilled or deionized water works for many peptides. Sterile water is preferable for in vivo applications. Buffered solutions may enhance stability by maintaining neutral pH.

Organic Solvents

Hydrophobic peptides (rich in hydrophobic amino acids like leucine, isoleucine, valine, phenylalanine, tryptophan) may require organic solvents or mixed solvent systems. Options include DMSO (dimethyl sulfoxide), a common solvent for hydrophobic compounds that completely miscible with water, allowing subsequent dilution, DMF (dimethylformamide), similar to DMSO but potentially more toxic, ethanol or methanol for some hydrophobic peptides, and acetic acid solutions (5-10% acetic acid) for certain difficult peptides.

Mixed Systems

For amphipathic peptides (having both hydrophobic and hydrophilic regions), mixed solvent systems work well. A common approach involves initially dissolving in a small volume of DMSO, then diluting with aqueous buffer. This achieves complete dissolution while minimizing organic solvent in the final solution.

Surfactants

For hydrophobic peptides requiring aqueous solutions, adding small amounts of surfactants can improve solubility. Options include Tween-20 (polysorbate 20) at 0.01-0.1%, Triton X-100 at similar concentrations, or specialized peptide solubilization agents. Be aware that surfactants may interfere with some biological assays.

pH Considerations

Many peptides contain ionizable groups (acidic or basic amino acids) whose charge states affect solubility. Acidic peptides (rich in aspartic acid, glutamic acid) often dissolve better at slightly basic pH (7.5-8.5). Basic peptides (rich in lysine, arginine) may dissolve better at slightly acidic pH (5.0-6.5). Neutral peptides typically dissolve well at physiological pH (7.0-7.4).

For pH adjustment, prepare solutions in appropriate buffers rather than adding acids or bases directly to peptide, which can create local pH extremes causing degradation.

Reconstitution Procedure

Follow these steps for optimal reconstitution:

- Calculate Required Concentration: Determine the final concentration needed based on your experimental design. Account for peptide content (not just gross weight) if specified on the certificate of analysis.

- Add Solvent Gradually: Add solvent slowly to the lyophilized peptide. Don’t immediately add the full volume; start with a portion (e.g., 50% of total volume) to assess solubility.

- Gentle Mixing: Mix gently by rolling the vial, swirling, or gently inverting. Avoid vigorous vortexing or shaking, which can denature or aggregate peptides. For stubborn peptides, gentle warming (37°C water bath for 5-10 minutes) may help, though avoid excessive heat.

- Allow Time to Dissolve: Some peptides dissolve quickly; others require 10-30 minutes. Be patient and allow adequate time before concluding a peptide won’t dissolve.

- Assess Complete Dissolution: The solution should be clear without visible particles or cloudiness. If particles remain, try additional gentle warming, mild sonication (brief pulses, not continuous), or alternative solvents if the current approach fails.

- Adjust to Final Volume: Once fully dissolved, add remaining solvent to achieve the desired final concentration.

Troubleshooting Solubility Issues: If a peptide won’t dissolve:

- Try alternative solvents (if current solvent isn’t dissolving, try DMSO, dilute acetic acid, or mixed systems)

- Adjust pH (add a small amount of dilute acid or base)

- Use mild heat (37°C, not boiling)

- Try brief sonication

- Consider that the peptide may have degraded or aggregated during storage

- Consult supplier technical support for sequence-specific recommendations

Reconstituted Peptide Storage

Once reconstituted, peptides are significantly less stable than lyophilized forms, requiring careful storage.

Short-Term Storage (Days to Weeks)

For peptides used within days, storage at 4°C is typically appropriate. Ensure the vial is tightly sealed to prevent evaporation and contamination. For peptides prone to oxidation, consider adding antioxidants like DTT (dithiothreitol) or β-mercaptoethanol at low concentrations (0.1-1 mM), though be aware these may interfere with some applications.

Use sterile technique to prevent microbial contamination, particularly for aqueous solutions. Consider adding preservatives like sodium azide (0.02-0.05%) for long-term storage, though not for in vivo applications as it’s toxic.

Long-Term Storage (Weeks to Months)

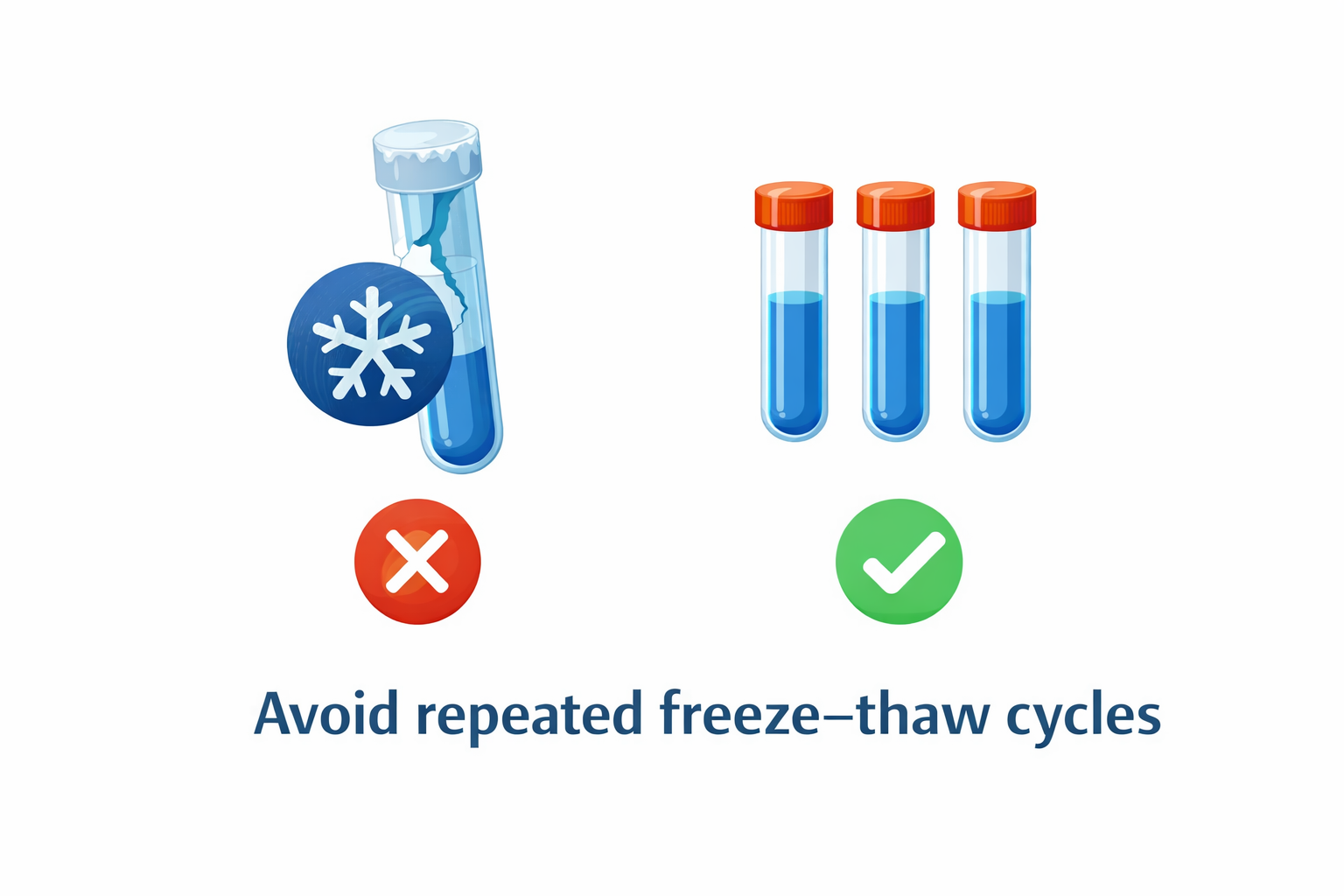

For extended storage of reconstituted peptides, freezing is essential. Store at -20°C or preferably -80°C. Avoid repeated freeze-thaw cycles, which progressively degrade many peptides. Aliquot the peptide solution into multiple single-use portions immediately after reconstitution to avoid freeze-thaw issues.

Add cryoprotectants for some peptides. Glycerol (10-50%) or trehalose can protect against freeze-thaw damage. Consider lyophilizing reconstituted peptides if they’ll be stored long-term, returning them to the more stable solid state.

Freeze-Thaw Considerations

Each freeze-thaw cycle subjects peptides to stress:

- Ice crystal formation can disrupt peptide structure

- Temperature fluctuations accelerate some degradation pathways

- Concentration changes occur as water freezes and thaws

- Aggregation can occur at the ice-liquid interface

Minimize freeze-thaw cycles by: aliquoting into single-use portions, thawing only what you need for immediate use, thawing gradually at 4°C or room temperature (not in a 37°C water bath), and mixing gently after thawing to re-homogenize the solution.

If a peptide must undergo multiple freeze-thaw cycles, verify integrity periodically by HPLC or bioassay.

Aliquoting Strategies

Creating single-use aliquots is one of the most effective strategies for maintaining peptide stability.

Aliquoting Lyophilized Peptides

For valuable or frequently-used peptides, consider aliquoting lyophilized material before reconstitution:

- Calculate appropriate aliquot sizes based on typical usage

- In a dry environment (ideally nitrogen or argon atmosphere, or at minimum a dry lab with desiccant), divide lyophilized peptide into smaller vials

- Seal each vial tightly

- Store all aliquots under optimal conditions

- Reconstitute individual aliquots as needed

This approach maximizes stability by keeping unused peptide in stable lyophilized form.

Aliquoting Reconstituted Peptides

More commonly, aliquot peptides after reconstitution:

- Reconstitute entire vial to desired concentration

- Immediately divide into appropriately-sized aliquots (e.g., 50-100 μL portions)

- Use appropriate containers (typically microcentrifuge tubes or small vials)

- Label each aliquot clearly with peptide identity, concentration, date, and batch number

- Freeze immediately

Container Selection

Choose appropriate containers for aliquoting:

- Polypropylene microcentrifuge tubes work well for most peptides and are inert to most solvents

- Low-binding tubes reduce peptide adsorption for very dilute solutions

- Glass vials are suitable for organic solvents and offer low peptide binding

- Avoid containers not rated for freezing temperatures

- Ensure tight seals to prevent evaporation and contamination

Working with Dilute Peptide Solutions

Dilute peptide solutions (<1 mg/mL) present special challenges due to increased surface adsorption and potential instability.

Minimizing Adsorption

At low concentrations, significant peptide fractions can adsorb to container surfaces:

- Use low-binding or siliconized tubes designed to minimize protein/peptide binding

- Add carrier proteins (0.1% BSA or 0.1% gelatin) to compete for binding sites, though verify this doesn’t interfere with your assay

- Maintain higher concentrations in stock solutions, diluting only immediately before use

- Pre-coat containers by rinsing with concentrated peptide solution, discarding rinse, then adding experimental sample

Stability at Low Concentrations

Dilute solutions may be less stable than concentrated stocks:

- Prepare dilute working solutions fresh from concentrated stocks

- Use dilute solutions promptly (within hours to a day)

- If storing dilute solutions, keep at 4°C rather than freezing (freeze-thaw is more damaging at low concentrations)

- Consider adding stabilizers (0.1% BSA, 10% glycerol, or supplier-recommended stabilizers)

pH and Buffer Considerations

Solution pH profoundly affects peptide stability and solubility.

Optimal pH Ranges

Most peptides are most stable near neutral pH (6-8):

- Acidic or basic pH accelerates hydrolysis for many sequences

- Extreme pH promotes racemization and deamidation

- However, some peptides require specific pH for solubility or activity

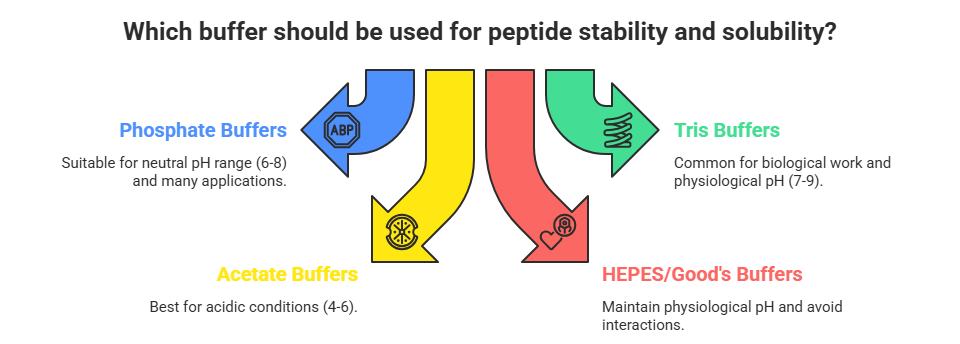

Use appropriate buffers to maintain stable pH:

- Phosphate buffers (pH 6-8) work for many applications

- Tris buffers (pH 7-9) are common for biological work

- Acetate buffers (pH 4-6) suit acidic conditions

- HEPES and other Good’s buffers maintain physiological pH

Avoid buffers that may interact with or degrade peptides. For example, amine-containing buffers can interfere with some coupling reactions.

Temperature Management

Temperature control is crucial throughout peptide handling.

During Storage

Keep peptides as cold as feasible for the storage duration:

- Long-term: -80°C for maximum stability or -20°C for most peptides

- Short-term: 4°C for working stocks used within days

- Never store at room temperature except for immediate use

During Handling

Minimize time at room temperature:

- Work quickly when accessing frozen stocks

- Keep working solutions on ice when possible during extended experimental procedures

- Return stocks to appropriate storage immediately after use

During Shipping

When receiving peptides or sending samples:

- Verify appropriate shipping conditions (dry ice for frozen, cold packs for refrigerated)

- Transfer to proper storage immediately upon receipt

- If temperature indicators show temperature excursions, consider the material compromised

Light Protection

Many peptides are photosensitive, requiring protection from light.

Photosensitive Residues

Tryptophan, tyrosine, and cysteine are particularly susceptible to photodegradation. Peptides containing these amino acids require extra light protection.

Light Protection Measures

- Use amber or opaque vials when available

- Wrap clear containers in aluminum foil

- Store in dark locations (closed drawers or boxes)

- Minimize light exposure during handling

- Use subdued lighting when working with photosensitive peptides

Contamination Prevention

Maintaining peptide purity requires preventing microbial and chemical contamination.

Microbial Contamination

Aqueous peptide solutions can support microbial growth:

- Use sterile technique when handling peptides for in vivo use

- Consider filter-sterilizing solutions through 0.22 μm filters

- Add preservatives (sodium azide, benzyl alcohol) for long-term aqueous storage (not for in vivo use)

- Store at 4°C or frozen to slow microbial growth

- Discard solutions showing cloudiness or visible growth

Chemical Contamination

Prevent introduction of degrading chemicals:

- Use clean, dedicated equipment for peptide handling

- Avoid contamination with oxidizing agents, reducing agents (unless intentionally added), or extremes of pH

- Don’t reuse containers without thorough cleaning

- Use high-purity solvents and reagents

Documentation and Tracking

Careful documentation supports reproducibility and troubleshooting.

Essential Records

- Date of reconstitution and storage conditions

- Solvent and buffer composition

- Final concentration

- Number of freeze-thaw cycles

- Any observations about solubility, appearance, or handling issues

- Aliquot labels with complete information

This documentation helps track peptide history, troubleshoot unexpected results, and ensure reproducibility across experiments.

Signs of Degradation

Recognizing potential degradation helps prevent use of compromised peptides.

Visual Indicators

- Cloudiness or precipitation in solution

- Color changes (many peptides are colorless; yellowing may indicate oxidation)

- Unusual odor (though many peptides are odorless)

- Failure to dissolve as expected

Analytical Verification

For critical experiments:

- HPLC analysis shows degradation through additional peaks or decreased main peak

- Mass spectrometry detects molecular weight changes from modification or degradation

- Bioassays reveal reduced activity compared to fresh peptide

When in doubt, verify peptide integrity before critical experiments.

Special Considerations for Specific Peptide Types

Certain peptide classes require special handling:

Cysteine-Containing Peptides

Prone to oxidation and disulfide bond formation:

- Add reducing agents (DTT, β-mercaptoethanol) to prevent unwanted oxidation

- Work under nitrogen or argon atmosphere when possible

- For peptides requiring disulfide bonds, ensure proper oxidative folding conditions

Lipopeptides

Contains lipid modifications that affect solubility:

- May require organic solvents or detergents for dissolution

- Can interact with surfaces more strongly than unmodified peptides

- May require special handling for biological assays

Phosphopeptides

Phosphate groups are susceptible to hydrolysis:

- Avoid phosphatase-containing buffers or conditions

- Store at acidic pH when possible (phosphates more stable at low pH)

- Verify phosphorylation by MS before critical experiments

Conclusion

Proper peptide storage and handling are essential for research success. By understanding degradation pathways, implementing best practices for storage, reconstitution, and handling, and carefully documenting peptide history, researchers protect their investment in quality peptides and ensure reliable, reproducible results.

The key principles include storing lyophilized peptides at -20°C or -80°C with desiccation, bringing to room temperature before opening to prevent moisture condensation, reconstituting carefully with appropriate solvents, aliquoting to avoid freeze-thaw cycles, storing reconstituted peptides frozen in single-use portions, protecting from light, temperature excursions, and contamination, and documenting all handling and storage conditions.

While these practices require some additional effort, they pay substantial dividends by maintaining peptide integrity, ensuring experimental success, and ultimately supporting high-quality research. Treating peptides with appropriate care from receipt through final use is an investment in research quality that every peptide user should prioritize.